Hi,

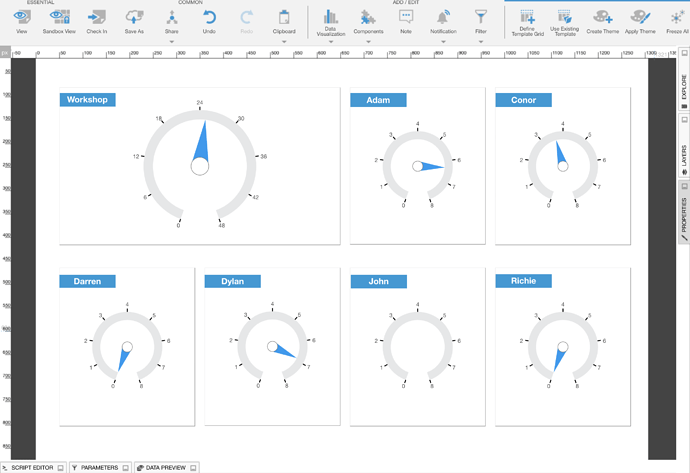

I am working on a dashboard (screenshot atatched) that shows the number of hours each fitter has worked (clocked on to jobs) during a day.

Each fitter has their own gauge and then the first gauge is the aggregated gauge; showing how many hours the team worked in total during the day.

First issue: one of the team worked more than the “maximum” number of hours of 8 in the day (8.16) so as I had set the gauges to be from 1 to 8, his gauge doesn’t show. Is there a way to have the gauge show even if the measure is greater than the max - or to set the min and max dynamically?

Second issue: I have set the aggregated gauge to be from 0 to 48 (being 6 fitters at 8 hours a day - which is the daily target for the team). However, if one of the team are out on leave or out sick (Richie in this case) then my overall target of 48 hours for the day is not correct. How do I get the aggregated gauge to “know” that the daily target is 40 (5 fitters at 8 hours per day) rather than 48 hours (6 fitters at 8 hours per day). Or can the user just enter a value (40) by a slider or something to set the overall aggregated target?

TC